Stress – strain diagram of Copper and copper alloys : -

Examples of the tensile stress-strain curves.

1- Electrolytic copper.

2- Commercial copper.

3- Bronze.

4- Cold worked copper (or cold drawn copper).

1- Electrolytic copper.

2- Commercial copper.

3- Bronze.

4- Cold worked copper (or cold drawn copper).

Stress – Strain diagrams of some standard steels :

The most important strength and ductility of the commercial steels are given as follows:-

Stress – Strain diagrams of some standard steels

Effect of heat treatment on the properties of steel found in tension test

The effect of heat treatment on the tensile stress-strain curves of the carbon steel is clearly shown fig. shows:-

- The hardened (quenched) steel shows no yield point and the smallest amount of elongation (greatest tensile strength).

- But if this steel is dead annealed a well defined yield point would appear and an appreciable elongation would result.

Stainless steels can be roughly divided according to the chemical compositions and

heat treatment into four groups with similar properties within each group: martensitic and ferritic-martensitic, ferritic, ferritic-austenitic, austenitic. Figure (b) shows the stress-

strain curves of different stainless steels.

Effect of temperature on the tensile properties of steel

Testing of metals by a tension test is usually carried out at room temperature.

For the application of material at higher temperature it is mandatory to test it at

the corresponding temperature. As a rule on raising the temperature at which the test is done the tensile strength decrease and the elongation and R.A. would increase.

Effect of testing velocity (rate of loading) on the tensile properties of metals : -

This effect is nearly obvious by all metals, If the rate of loading is increased, the yield stress and tensile strength would also increase, while the percent elongation and reduction of area decrease.

the normal rate of loading for static tension test is not more 1 kg/mm in one second.

Or in the term of strain rate it is around the 0.001 sec-1 .

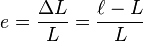

Stress-strain diagram of different forms of tensile specimen :-

d = test diameter D = head diameter Lo = test length Lc = gauge length:

L = total length

Sudden change in cross section causes stress concentration so that a fillet with certain radius is necessary as transition diameter between the test diameter and the head diameter.

Surface finish: The degree of surface finish is also an important parameter in the

quality of the produced test specimens and controls the results of the test. Grinding of

the specimen using silicon carbide grinding papers with a grade of higher than 600 grit

could be a satisfactory surface finishing tool.

Standardization

Long proportional specimens

Lo = 10 d or Lo = 11.3 √ Ao

short proportional specimens

Lo = 5 d or Lo = 5.65 √ Ao

Ao is the initial area of specimen at the test length

n case of flat, quadratic or other shapes we take referred to specimen’s area A0 (A0 = a

. b, where a is the thickness and b is the width of the test length) using the relations:

Effect of heat treatment on the properties of steel found in tension test

The effect of heat treatment on the tensile stress-strain curves of the carbon steel is clearly shown fig. shows:-

- The hardened (quenched) steel shows no yield point and the smallest amount of elongation (greatest tensile strength).

- But if this steel is dead annealed a well defined yield point would appear and an appreciable elongation would result.

Stainless steels can be roughly divided according to the chemical compositions and

heat treatment into four groups with similar properties within each group: martensitic and ferritic-martensitic, ferritic, ferritic-austenitic, austenitic. Figure (b) shows the stress-

strain curves of different stainless steels.

Effect of temperature on the tensile properties of steel

Testing of metals by a tension test is usually carried out at room temperature.

For the application of material at higher temperature it is mandatory to test it at

the corresponding temperature. As a rule on raising the temperature at which the test is done the tensile strength decrease and the elongation and R.A. would increase.

Effect of testing velocity (rate of loading) on the tensile properties of metals : -

This effect is nearly obvious by all metals, If the rate of loading is increased, the yield stress and tensile strength would also increase, while the percent elongation and reduction of area decrease.

the normal rate of loading for static tension test is not more 1 kg/mm in one second.

Or in the term of strain rate it is around the 0.001 sec-1 .

Stress-strain diagram of different forms of tensile specimen :-

d = test diameter D = head diameter Lo = test length Lc = gauge length:

L = total length

Sudden change in cross section causes stress concentration so that a fillet with certain radius is necessary as transition diameter between the test diameter and the head diameter.

Surface finish: The degree of surface finish is also an important parameter in the

quality of the produced test specimens and controls the results of the test. Grinding of

the specimen using silicon carbide grinding papers with a grade of higher than 600 grit

could be a satisfactory surface finishing tool.

Standardization

Long proportional specimens

Lo = 10 d or Lo = 11.3 √ Ao

short proportional specimens

Lo = 5 d or Lo = 5.65 √ Ao

Ao is the initial area of specimen at the test length

n case of flat, quadratic or other shapes we take referred to specimen’s area A0 (A0 = a

. b, where a is the thickness and b is the width of the test length) using the relations: